Device for nitrogen control: Optimizes the sludge process functioning reducing energy consumption

Description

Characteristics

Images

Description

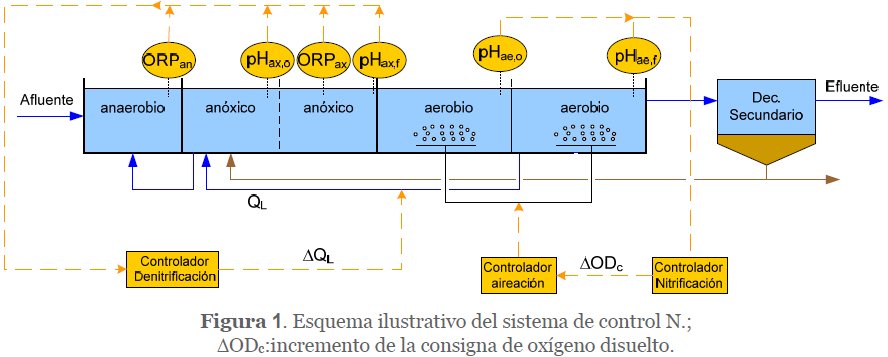

The control system consists of two independent controllers for the nitrification and denitrification process, respectively. The nitrification process controller acts on the dissolved oxygen set point of the aerobic reactor according to the measurement of two pH probes. From these values the evolution of the nitrification potential of the aerobic stage is evaluated, this information is very relevant to control more precisely the nitrification process.

The controller acts as a supervisory control modifying the dissolved oxygen (DO) in the different existing aerobic zones. It should be noted that the difference in pH gives more information about the nitrification process, compared to the use of an ammonium analyzer, distinguishing whether the process is limited or not by the dissolved oxygen concentration. In this way, this controller saves energy because it only increases the set amount of dissolved oxygen in cases where it is really necessary to remove the ammonium.

In addition, working with low DO values favors the biochemical pathway of nitrogen removal through nitrite (“nitrite shortcut”), which saves 25% oxygen in the nitrification and 40% organic matter in the denitrification, compared to nitrogen removal via nitrate. The denitrification process controller acts on the internal recirculation rate of the aerobic to anoxic reactor according to the measurement of two pH and two redox potential probes.

From the measurements of the two pH probes, information about the denitrification capacity of the anoxic stage is obtained. With the values of the redox potential, the existing nitrate concentration and the proximity to anaerobic conditions at the end of the anoxic stage are obtained indirectly. This control algorithm acts according to the denitrification capacity of the anoxic stage and the concentration of nitrate in the last anoxic stage. The control system only increases the internal recirculation rate in case the nitrate concentration in the last anoxic stage is low (reflected by a low redox potential), and the anoxic stage shows a greater denitrification capacity (reflected by the evolution of the pH difference in the anoxic stage), eg. when the process has sufficient capacity to denitrify the nitrate from this recirculation. For this reason, this control system also minimizes the energy cost derived from pumping costs.

Characteristics

The control system consists of two independent controllers for the nitrification and denitrification process, respectively. The nitrification process controller acts on the dissolved oxygen set point of the aerobic reactor according to the measurement of two pH probes. From these values the evolution of the nitrification potential of the aerobic stage is evaluated, this information is very relevant to control more precisely the nitrification process.

The controller acts as a supervisory control modifying the dissolved oxygen (DO) in the different existing aerobic zones. It should be noted that the difference in pH gives more information about the nitrification process, compared to the use of an ammonium analyzer, distinguishing whether the process is limited or not by the dissolved oxygen concentration. In this way, this controller saves energy because it only increases the set amount of dissolved oxygen in cases where it is really necessary to remove the ammonium.

In addition, working with low DO values favors the biochemical pathway of nitrogen removal through nitrite (“nitrite shortcut”), which saves 25% oxygen in the nitrification and 40% organic matter in the denitrification, compared to nitrogen removal via nitrate. The denitrification process controller acts on the internal recirculation rate of the aerobic to anoxic reactor according to the measurement of two pH and two redox potential probes.

From the measurements of the two pH probes, information about the denitrification capacity of the anoxic stage is obtained. With the values of the redox potential, the existing nitrate concentration and the proximity to anaerobic conditions at the end of the anoxic stage are obtained indirectly. This control algorithm acts according to the denitrification capacity of the anoxic stage and the concentration of nitrate in the last anoxic stage. The control system only increases the internal recirculation rate in case the nitrate concentration in the last anoxic stage is low (reflected by a low redox potential), and the anoxic stage shows a greater denitrification capacity (reflected by the evolution of the pH difference in the anoxic stage), eg. when the process has sufficient capacity to denitrify the nitrate from this recirculation. For this reason, this control system also minimizes the energy cost derived from pumping costs.